Standing Seam UAE | ARCO Standing Seam VS Conventional Roofs

Standing Seam UAE –

Standing seam is a structural roof system with mechanical field joints to improve resistance to weather and wind. Standing seam UAE roofing sheets are available in conical and curved shapes to meet a variety of building design requirements.

- Lifespan

Corrugated metal roofs are installed with fasteners that are exposed to the elements. the screws will eventually back out and the holes in the panels will enlarge and it will leak,

All corrugated metal roofs need to have the fasteners inspected and tightened at least once a year . Standing seam metal roofs do not require this type of routine maintenance thanks to their concealed fasteners.

- Wind Resistance

The exposed fasteners of the corrugated panels must be tightened regularly so the wind can’t work the panels loose. In areas where high winds are very common,

the fasteners should be inspected and tightened regularly

With Standing seam metal roofs the wind should not be a problem. The panels side joints are locked and zipped tightly together.

- Air and Water Tightness

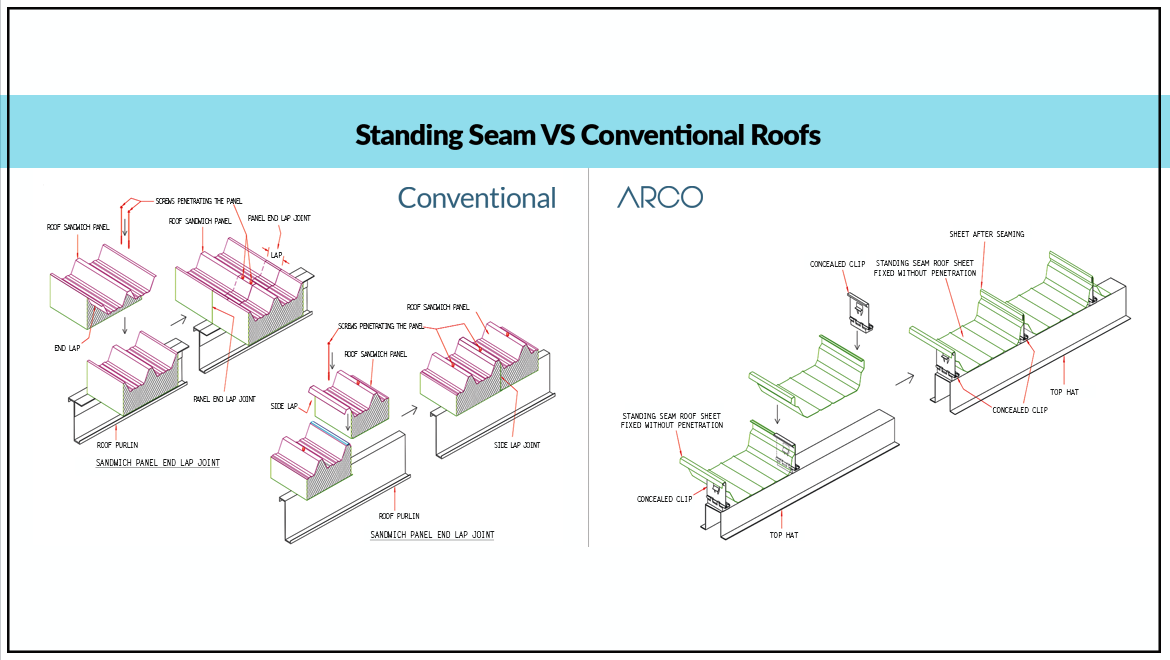

Due to the joining details of the conventional roofing system , the small length of the panels and the needs for end laps connection details, the exposed fasteners and the reaction to the floating action of the metal sheet , doesn’t help the system to maintain its Air and water tightness integrity.

Standing Seam UAE

- Design Potential

The design of conventional roofing systems is very limited compared to the standing seam system, which allows for unlimited design flexibility to accommodate the market trends in that sector.

- Appearance and Finishing

Exposed fastened panels use a screw or nail to secure the metal roofing to the purlins. This can involve hundreds and even thousands of fasteners, which must be spaced and driven to maintain the integrity of their rubber washer which serve to prevent precipitation from gaining access through each hole.

Conversely, concealed clip fastened panels use a system where the fasteners are driven through the clips into the roof deck with no connection or piercing of the metal panels. The clip and fasteners are concealed beneath the standing seam panel material. The panel is then laid over and attached to the clips and then mechanically locked.

- Float Action

Metal expands and contracts with temperature change, with exposed fastener roofs , screws driven too tight leave no room for expansion and contraction. In contrast, a concealed fastener system is driven through the clip and not the panel itself and is designed to flex or move under the panel.

And of course, the concealed fasteners are never exposed to the weather and are insulated from the movement.

- Cost Impact

Exposed fastener metal roofing panels are a less expensive alternative to standing seam roofs, however, the additional maintenance expenses and the possibility of roof replacement should be considered.

It is definitely not an “install it and forget it” type of roof. Standing seam metal roof will last significantly longer than corrugated metal roofs. It is the ideal system for low slope roof, which require less structural materials and reduce material costs. it’s a smart investment in your Building.

- ARCO

- roofing company in dubai

- Standing Seam

- standing seam dubai

- Standing Seam UAE

- uae standing

- uae standing seam